Green energy industry resource processing micro-nano processing equipment technology technology

Submitted by superGreen energy industry resource processing micro-nano processing equipment technology technology

1. Life science and biotechnology equipment

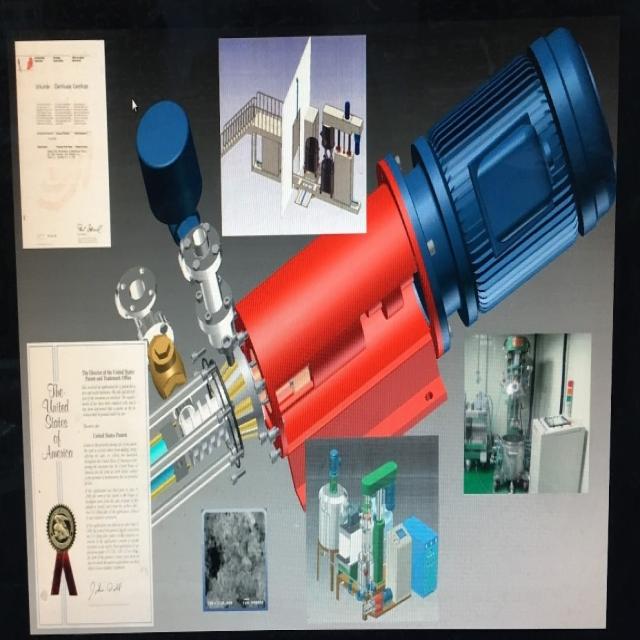

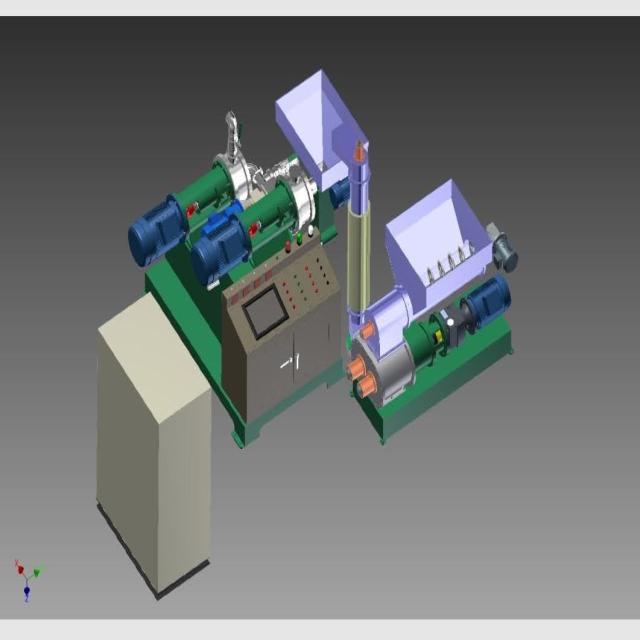

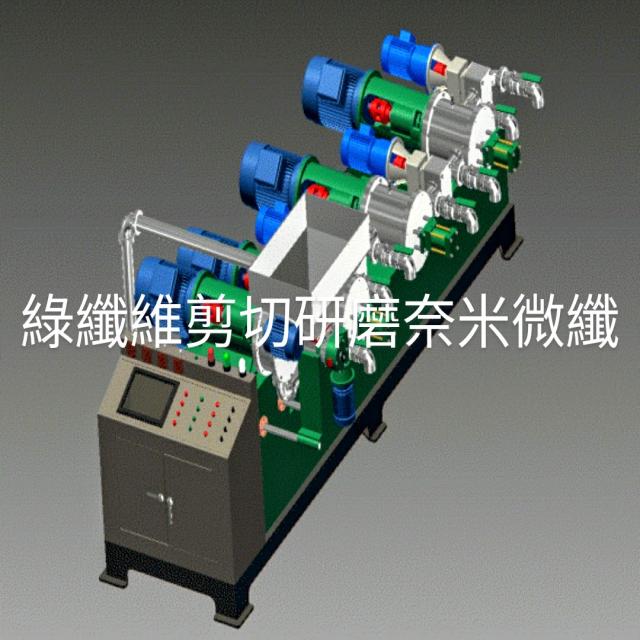

A. Semi-dry fiber shearing micro-nano powder processing equipment without bottom temperature: agricultural, fish and animal husbandry fiber food, chemical mineral carbon reactive fiber, plant fiber energy fuel, plant Chinese medicinal fiber, lithium power storage and fuel power storage raw materials, nitrocellulose,

Organic and inorganic fibers and minerals, etc. (crushing, grinding, refining).

B. Liquid-wet fiber shearing micro-nano paste bottom temperature processing equipment: agricultural, fish, animal husbandry fiber food, chemical mineral carbon reactive fiber, plant fiber energy fuel, plant Chinese herbal medicine fiber, lithium battery storage and fuel storage, paint, ink , Rubber paste, cosmetics, organic-inorganic and mineral paste and other nano-processing (stirring, mixing, grinding, refinement) sewage treatment equipment.

2. Renewable energy biofuel technology equipment

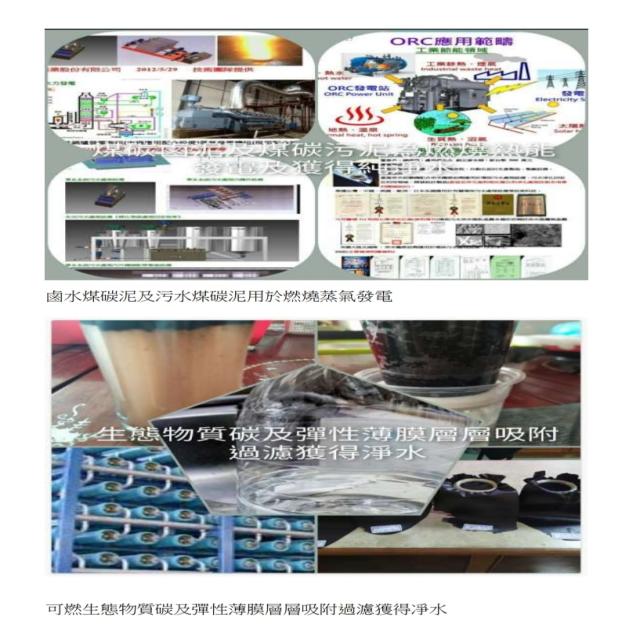

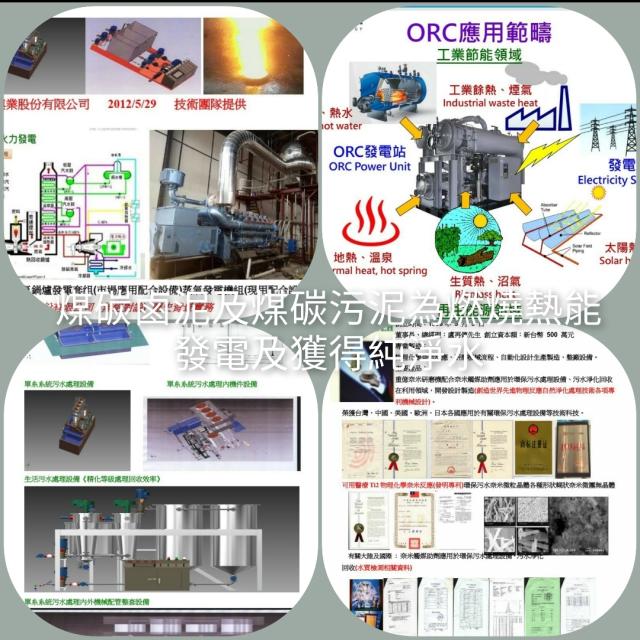

A. Sewage treatment purification combustion sludge, sewage particulate grinding nano catalyst (physical and chemical spontaneous combustion reaction treatment technology) conversion of combustion heat energy, energy saving and carbon reduction.

B. (Coal carbon particles and Ti2 physical and chemical nanometer, sewage slurry, heavy oil, with man-machine computer automatic analysis, calculation, monitoring and modification of the ratio of 0-40% sludge slurry conversion combustion heat, using (international patent grinding technology) The explosion of micro-molecules of burning water at a furnace temperature of 500 degrees into hydrogen ions will increase the value of the combustion heat energy card).

3. Biotechnology equipment for slaughterhouse bone finishing

A. (Jiankang Food Live Glue) can be used as a high added value (basic material elements for food construction and other applications)?

B. Insoluble in water, insoluble in boiling water, equal to 100% gum, which is very beneficial to the lack of elements in human body function. (Jiankang Food Live Gum Calcium Meat Gum Powder) is a functional supplement food.

4. Agricultural soil recycle and plant biotechnology equipment

A. Manufacturing process: Poor soil, weeds, grass, tree trunks and thinning soil are added proportionally with purified functional water and proportional fibers (using physical reaction, natural chemical processing technology, various patented mechanical power operation concepts, magnetic field energy, high thermal energy catalyst burst It reacts, decomposes the cellulose of plants, leaves and branches, and the polysaccharides contained in it converts monosaccharide alkalis into lactic acid bacteria liquid (air-containing soil).

5. Technical equipment for the reduction and conversion of waste tire rubber products

A. No absolute theory (natural physical and chemical natural return to the original recycled rubber production and manufacturing; Sinosteel composite rubber water filter grid) Transcendence technology, hardware and software, no literature available in the world?. At present, advanced countries in the world deal with waste tire technology ?. The first type of treatment is to use crushing, desulfurization, refining, and regenerating fillers. The second type of treatment is when fuel is burned. The secondary pollution of the air is ultrafine carbon black, which wastes natural resources, destroys the environment and poisons the public.

6. Agro-forestry plant fiber mixed chain PLA plastic manufacturing packaging paper technology equipment

A. Rice stalk natural plant and polylactic acid manufacturing, physical mechanical extrusion of mixed chain film making, paper making, PLA heat-resistant technology and equipment are the main, physical mechanical mixed chain injection, how to improve PLA heat-resistant technology and equipment for electrical products, in traditional physical machinery Extrusion and injection molding machinery and equipment cannot improve the heat resistance of PLA. Agro-forestry plant fiber mixed chain PLA plastic manufacturing packaging paper technology equipment, rice straw natural plant polylactic acid manufacturing can improve farmers' economic benefits, and at the same time create an advanced energy-saving and carbon-reducing green industry.

7. Rice husk cement additive application building surface material biotechnology product

A Nissan energy-saving, carbon-reducing and purifying building surface materials, natural physical functions: environmental protection, energy-saving, carbon-reduction, purification, health care, energy?

B. Rice husk natural plants, but burning equals carbon pollution. Using rice husk plants with natural interlaced woven fiber pores, thin tubes containing plant starch acid wax, and adding concrete slurry in construction instead of high molecular weight materials can indeed reduce Issues such as carbon, energy-saving, emissions and pollution.

The hazards of human housing and the progress of industry and commerce, and the wealthy economic enjoyment, must require decorative building materials to be rich and noble, and to directly contact the human living environment for a long time. The main causes of chronic diseases are: 1. ˚c Fluorescent lamps above irradiate to produce heat, vapor, chemical reaction, halogen inhalation into human body.